- Tel: +44 (0) 208 305 0792

- FAX: +44 (0) 208 858 0101

- info@stoneleigh-eng.com

Pressure Reducing Valves

Please click HERE for general information on Reducing Valves

We are able to offer a comprehensive range of Reducing Valves to meet most requirements

For all order enquiries please contact us on: +44 (0) 208 305 0792 or email: info@stoneleigh-eng.com

Reducing Valves - examples: Butterfly, Globe, Poppet etc.

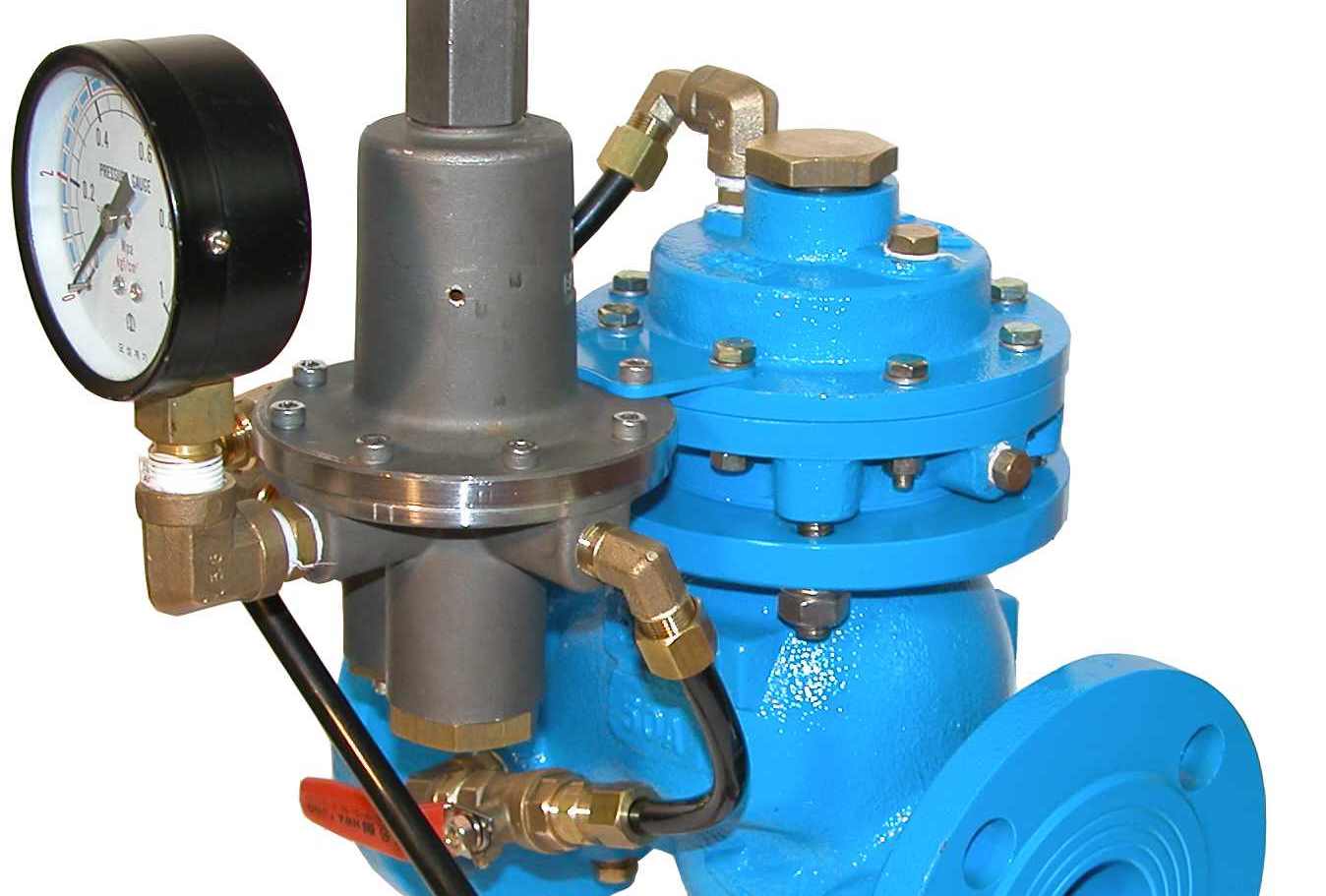

Pressure Reducing Valves

The prime function of the pressure reducing valve is to match the flow through the regulator to the demand placed upon the system. It may be a butterfly valve, globe valve, poppet valve, or any other type of valve that is capable of operating to vary the flow restriction.

If the load flow decreases, then the regulator flow must decrease as well. If the load flow increases, then the regulator flow must increase in order to keep the controlled pressure from decreasing due to the flow shortage in the pressure system..

Please contact us with your requirements

Pressure Reducing Valves

Pressure Reducing Valve is an automatic control type valve designed to reduce a higher inlet pressure to a lower constant outlet pressure regardless of fluctuating flow rates and or varying inlet pressure.

Typically it is a pilot controlled. It is hydraulically operated, diaphragm actuated valve in either the oblique or angle pattern design. Valve differential pressure powers the diaphragm actuator open or closed.

The lower control section or chamber is connected through a fixed opening to the downstream pressure, which serves to cushion the closing of the valve.

The upper control section operates on a two-way control basis. It has varying pressure produced by the regulating pilot and the pilot's internal upstream restriction needle valve.

The pressure regulating pilot senses downstream pressure and modulates closed or open. This action will vary the pressure in the upper control section causing the main valve to throttle thereby maintaining constant delivery pressure.

When the downstream pressure falls below the pre determined pilot setting, the pilot opens, pressure in the upper control section decreases, and the main valve modulates open to increase downstream pressure and maintain pilot setting.

Should the downstream pressure increase above the pilot setting, the pilot closes, pressure in the upper section increases and the main valve throttles close to decrease downstream pressure to the pilot setting.

The Pressure Reducing pilot has an adjusting screw to preset the desired downstream pressure to the agreed level and an internal needle valve to control the closing speed.