- Tel: +44 (0) 208 305 0792

- FAX: +44 (0) 208 858 0101

- info@stoneleigh-eng.com

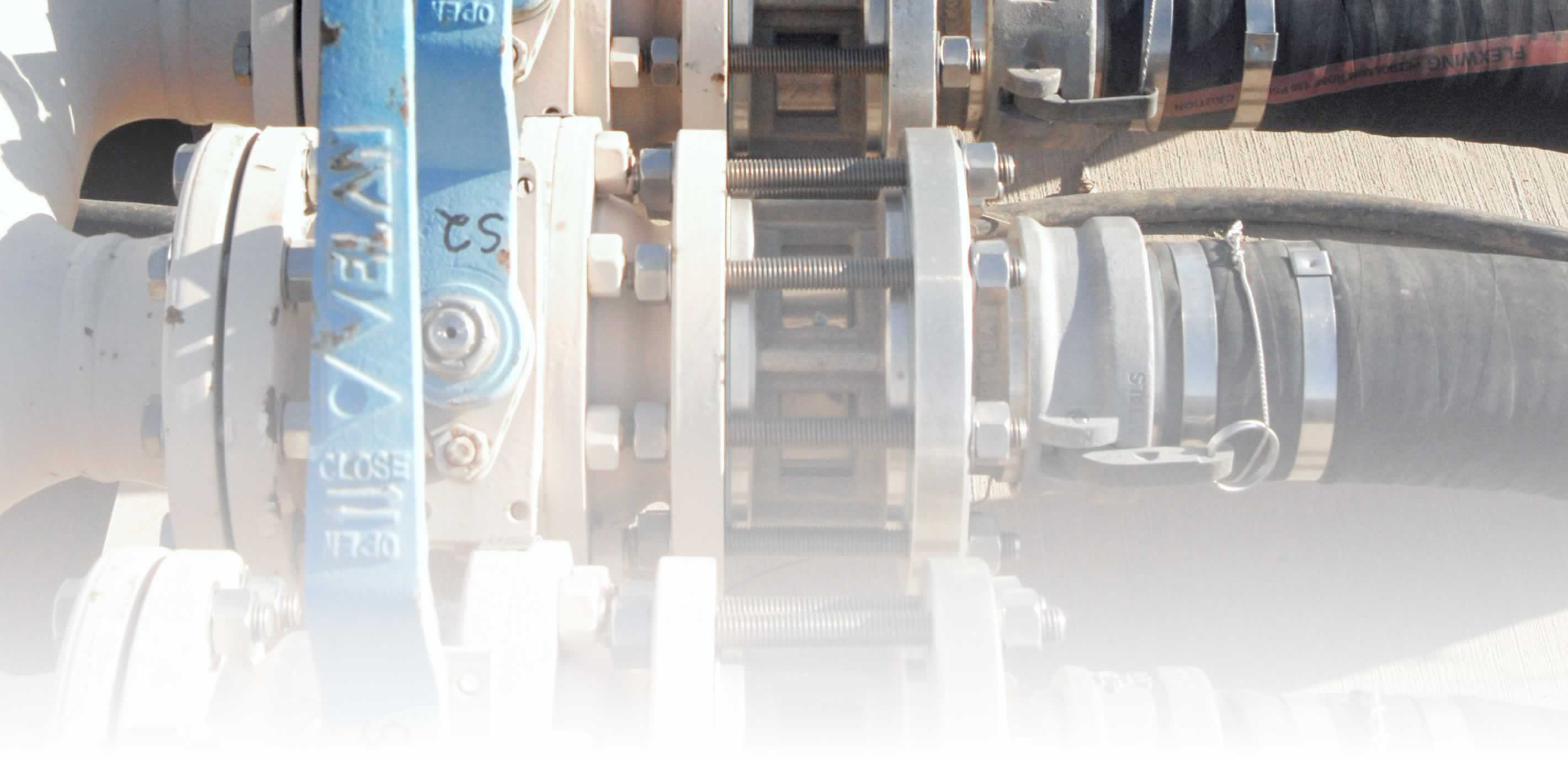

Pipe Fittings

Please click HERE for general information on Pipe Fittings

We are able to offer a comprehensive range of Pipe Fittings to meet most requirements and applications

For all order enquiries please contact us on: +44 (0) 208 305 0792 or email: info@stoneleigh-eng.com

Steel Pipping, Copper Tubing, Plastic Pipping, Aluminium Tubing plus more...

Pipe Fittings are used to connect piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work covers supply and installation of new plus repair of existing.

Please contact us with your requirements

Pipe Fittings

Steel Pipe

Steel pipe (or black iron pipe) was once the most popular choice for supply of water and flammable gases, but fell from favor as water pipe in the mid 20th century due to its tendency to rust. Steel pipe is still used in many homes and businesses to convey natural gas or propane, and is a popular choice in fire sprinkler systems due to its high heat resistance.

Steel pipe is joined using thread connections, where tapered threads are cut into the tubing section end, sealant is applied in the form of thread compound or PTFE tape (similar to teflon tape) and it is then threaded into a corresponding threaded fitting using a pipe wrench.

Usages vary from country to country as different nations have different standards to install pipe.

Regarding natural gas (NG) and propane (LP gas), black iron pipe (BIP) is used to connect an appliance to the supply, it must however be marked (either painted yellow or yellow banding attached at certain intervals) and certain restrictions apply to which nominal pipe size (NPS) can be put through walls and buildings. With propane in particular BIP can be run from an exterior tank (or cylinder) provided it is well protected from the elements and an anode-type of protection is in place for when the pipe is to be installed underground.

Copper tubing

Copper tubing is most often used for supply of hot and cold water, and as refrigerant line in HVAC systems. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, or sweat (solder). Copper offers a high level of resistance to corrosion, but is becoming very costly.

Soft copper

Soft (or ductile) copper tubing can be bent easily to travel around obstacles in the path of the tubing. While the work hardening of the drawing process used to size the tubing makes the copper hard/rigid, it is carefully annealed to make it soft again; it is therefore more expensive to produce than non-annealed, rigid copper tubing. It can be joined by any of the three methods, and it is the only type of copper tubing suitable for flare connections. Soft copper is the most popular choice for refrigerant lines in split-system air conditioners and heat pumps.

Flare connections

Flare connections require that the end of a tubing section be spread outward in a bell shape using a flare tool. A flare nut then compresses this bell-shaped end onto a male fitting. Flare connections are the most labor intensive of the three options, but are quite reliable over the course of many years.

Rigid copper

Rigid copper is a popular choice for water lines. It is joined using a sweat, compression or crimped/pressed connection. Rigid copper, rigid due to the work hardening of the drawing process, cannot be bent and must use elbow fittings to go around corners or around obstacles. If heated and allowed to slowly cool, called annealing, then rigid copper will become soft and can be bent/formed without cracking.

Sweat connections

Sweat fitting. These are smooth, and easily slip onto the end of a tubing section. The joint is then heated using a torch, and solder is melted into the connection. When the solder cools, it forms a very strong bond which can last for decades. Sweat connected rigid copper is the most popular choice for water supply lines in modern buildings. In situations where many connections must be made at once, (such as plumbing of a new building) sweat offers much quicker and much less expensive joinery than compression or flare.

Compression connections

Compression fittings use a soft metal ring (the compression ring) which is squeezed onto the pipe and into the fitting by a compression nut. The soft metal conforms to the surface of the tubing and the fitting, and creates a seal. Compression connections do not typically have the long life that sweat connections offer, but are advantageous in many cases because they are easy to make using basic tools. A disadvantage in compression connections is that they take longer to make than sweat, and sometimes require retightening over time to stop leaks.

Crimped or pressed connections

Crimped or pressed connections use special copper fittings which are permanently attached to rigid copper tubing with a powered crimper. The special fittings, manufactured with sealant already inside, slide over the tubing to be connected. Thousands of pounds-force per square inch of pressure are used to deform the fitting and compress the sealant against the inner copper tubing, creating a water tight seal. The advantages of this method are that it should last as long as the tubing, it takes less time to complete than other methods, it is cleaner in both appearance and the materials used to make the connection and no open flame is used during the connection process. The disadvantages are that the fittings used are harder to find and cost significantly more than sweat type fittings.

PVC and CPVC

PVC or polyvinyl chloride, is the most popular choice in plastic pipe. It is rigid, and uses thread or solvent weld (glue) connections, it also can be heat fused. It is available in various pressure ratings, with the most common choice being Schedule 40 for pressurized uses, it is available for waste water lines. Standard PVC can only be used for cold water supply, and is a very popular choice for landscape irrigation. CPVC is a different type of plastic, which has an extra chlorine atom in the compound. It can be used for the hot water supply, and in industry.

Polyethylene

Polyethylene or PE pipe is often used for the supply of hot and cold water. It can be joined using barb-fittings with clamp rings, or it can be heat-fused (sections can be melted together) using an appropriate tool. Because PE pipe is flexible, it can be curved through a radius to make turns, and thus avoid the complexity and expense of fittings required to make turns with other types of piping. Undyed PE is colorless, and uncolored PE tubing has a frosted, translucent appearance. Colored varieties include red, blue, black, gray and white. PEX (cross linked polyethelyne) is a popular choice for underground loops in geothermal heating, as supply line for lawn sprinkler systems and in water supply applications.

Rigid Polypropylene

Sections and fittings can be heat fused or threaded together. Heat fusing is a two-person job requiring specialized equipment and therefore is not commonly done. Comes in black or opaque white. Has the advantage of higher temperatures than PVC.

ABS

ABS or acrylonitrile butadiene styrene is recognizable by its rigidity and black color. It is used only for drainage lines and is lower in cost than PVC.

Nylon

Nylon tubing is often used for water lines inside appliances, and to convey various flammable fluids and solvents. It offers high resistance to chemical reaction.

Aluminium tubing

Aluminium is sometimes used due to its low cost, resistance to corrosion and solvents, and for its ductility. Aluminium tube is more desirable than steel for the conveyance of flammable solvents, since it cannot create sparks when manipulated. Aluminium tubing can be connected by flare or compression fittings, or it can be welded by the TIG or heliarc processes.